Description

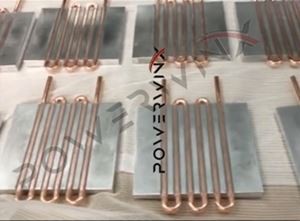

Standard Liquid Cold Plates is a device used for efficient thermal management, and is typically used in applications with high heat dissipation requirements. It is made of metal materials (such as aluminum or copper), and fluid channels are formed internally through precision machining. These channels carry heat away from electronic components or systems that need to be dissipated through the flow of coolant. The structure of the liquid-cooled cold plate includes a contact surface that is in direct contact with the heat source, conducts heat to the coolant through thermal conductive materials, and then carries the heat away through the flow channel to complete the heat exchange process. The outside of the cold plate is usually equipped with an interface for connecting to the pipes of the cooling system to form a complete liquid cooling system.

Polishing the surface Production line

Features

Alright, let's cut through the tech jargon and spell this out like a real human:

You've got these standard liquid cold plates, right? They're basically made from extruded aluminum (cheaper, but still does the job), and they run a single, unbroken copper tube right through the thing. Why does that matter? Well, aluminum's not bad at spreading heat around (about 150 W/m·K, if you're into specifics), but copper's a beast-hits something wild like 400 W/m·K! Basically, it'll yank heat outta there way faster.

Oh, and there's no annoying welded seams or joints in the middle of the pipe like the old-school versions. That means less spots where heat gets stuck, 'cause every connection just slows things down. The copper tube shuttles the heat straight to the coolant with way less fuss. So, yeah, with this setup, the cold plate doesn't freak out under heavy workloads-it just keeps on cooling like a champ. No drama.

Continuous copper tube design reduces the risk of leakage

Alright, here's the lowdown: Instead of messing around with a bunch of welded joints like the old-school cold plates, these Standard Liquid Cold Plates just roll with a seamless, continuous copper tube. No random connection spots, no sketchy welds-just one smooth piece running the whole way through. What's that mean? Way less chance your coolant's gonna spring a leak (which, trust me, is a nightmare nobody wants).

Plus, sealing's tight, like Fort Knox. You get solid long-term stability, which is a fancy way of saying it doesn't randomly crap out halfway through doing its job. So, if you're pushing your system in high-pressure or sizzling-hot conditions, this thing's not gonna flinch. No freaky leaks. No sad, slumping cooling performance. Just steady-as-she-goes operation. Honestly, that's a major upgrade compared to the usual cold plate circus.

High thermal conductivity epoxy adhesive bonding technology

Alright, let's break this down in plain English. So, when folks make Standard Liquid Cold Plates, they basically grab a copper tube and stick it onto an aluminum base using this fancy, high heat-conductive epoxy goo. Why? Well, for starters, this stuff sticks like a champ-no wimpy glue business here-and it actually helps pull heat away way better than the old-school glues. We're talking thermal conductivity in the ballpark of 1.5 to 3 W/m·K. That might sound like engineer-speak, but bottom line: it's miles better than the basic adhesives your dad probably used to fix the toaster. With this epoxy, you dodge those annoying issues like heat getting bottlenecked 'cause the glue wasn't playing ball, or stuff coming loose and ruining the cooling. It's just a smarter way to keep things chill-literally.

High performance and leaky joints

Due to the continuous copper tube design and high thermal conductivity epoxy adhesive bonding process, Standard Liquid Cold Plates have excellent leakage protection capabilities. There are no welding points at the joints of the cold plate, which reduces the common risk of leakage, ensures stable coolant flow, and maintains the efficient heat dissipation function of the system. Water leakage not only affects the working efficiency of the cold plate, but may also cause system failure. Therefore, avoiding leakage is the key to ensuring the long-term stable operation of the liquid cooling system. This design ensures that users can use it safely and stably in harsh environments.

FAQ

Q: Where are you located?

A: We are located on Dongguan, Guangdong, China .

Q: Are you ISO certified?

A: Yes, we are ISO 9001:2015 and IATF certified.

Q: What type of CAD files are accepted?

A: We can accept most CAD file formats (e.g. STEP, IGES, etc.) .

Q: What kind of industries do you serve?

A: We produce customized products based on our customer's design, so we serve customers that are involved in the semi-conductor and computer, medical devices/equipment, aerospace, electronics , automotive industries and etc....

Hot Tags: standard liquid cold plates, China standard liquid cold plates manufacturers, suppliers, factory, on time die casting delivery, cnc machining for offset printing, full service die casting, rapid prototyping cnc machining, cnc machining for fabrication, quality cnc machining