Copper Skived Fin Heat Sink

Introduction

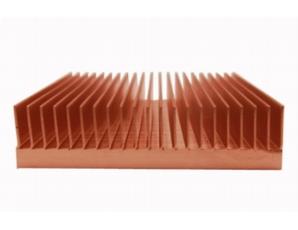

The copper cut-fin heat sink is a heat exchange device made of copper material and processed by the cut-fin process. Its basic structure includes a copper base plate and several thin and fine fins connected to the base plate. The fins are precisely cut out from the copper base plate by the cut-fin process to form a uniform structure. These fins are closely arranged to maximize the heat dissipation surface area and enhance the heat conduction and dispersion capabilities. The manufacturing process of the entire heat sink ensures a good connection between the fins and the base plate, so that the heat can be efficiently transferred from the heat source to the fins, and then diffused to the surrounding environment through the surface of the fins.

|

|

| Copper skived fin heat sink process | Close view of copper skived fins |

Features

Superior thermal conductivity

Copper has one of the highest thermal conductivity of all common metal materials, about 385 W/m·K, which makes copper cut-fin heat sinks particularly good in heat conduction. The fin design of the copper heat sink can maximize the thermal conductivity of copper, and ensure that the heat can be quickly diffused by directly transferring heat from the source to the fins. This efficient heat transfer capability enables the copper cut-fin heat sink to maintain efficient heat dissipation under high heat load environments.

Ability to adapt to high temperature environments

Compared with other metals, copper's high melting point and high temperature resistance make it perform better in extreme working environments. The maximum operating temperature of copper material can reach 250°C, and the copper cut-fin heat sink can maintain stable heat dissipation performance for a longer time in an environment with large temperature fluctuations. Under some high temperature conditions, the advantages of copper are particularly obvious, which can avoid the degradation of heat dissipation performance due to overheating.

Higher fatigue and corrosion resistance

Copper's fatigue resistance and corrosion resistance under long-term working conditions make it more durable in complex environments. Especially in high humidity, marine climate or chemical corrosion environment, copper has stronger corrosion resistance than metals such as aluminum, and can maintain its performance for a long time and reduce equipment failure. Copper cut fin heat sinks are often used in high-end electronic products and industrial equipment that require long-term stable operation due to their excellent durability.

Optimized fin design

Copper cut fin heat sinks use a precision cutting process to produce high-density, uniformly thick fins in a very short time. Compared with other types of heat sinks, copper cut fins can achieve a higher density of fin arrangement, thereby providing more surface area in the same volume and improving heat exchange efficiency. This precision manufacturing process not only ensures the high efficiency of the heat sink, but also can adapt to the heat dissipation needs of different applications.

OEM copper skived fin heat sink

Specification

|

Item name |

OEM copper skived fin heat sink |

|

Material |

Copper |

|

Surface finish |

Antioxidant |

|

MOQ |

500 PCS |

|

L/T |

30 days for mould and 7-10 days for sample |

|

Size |

90*90*25 mm |

|

Packing |

Safety packing |

|

Application |

Semiconductor |

Delivery,Shipping

FAQ

Q: If I send you a 3D CAD (STEP) file, why do you need 2D drawings?

A: The 3 CAD files are helpful, but most do not include tolerances or additional notes that may apply to the part, which is why the 2D drawings are needed.

Q: What materials do you offer?

A: We offers aluminum and copper for skived fin heat sinks.

Q: How about the payment term?

A: T/T, PayPal, L/C, it depends on order amount.

Q: After payment, if we have quality issue, how soon can we get the replacement ?

A: If have quality issue, we will see whose fault is. If it is our mistake, we will arrange replacement within 15-20 days, lead time is dependent on quantity and product structure.

Hot Tags: copper skived fin heat sink, China copper skived fin heat sink manufacturers, suppliers, factory, production cnc machining, gravure printing cnc machining, automated die casting, defect detection in die casting, engineering cnc machining, painting die casting