Skiving Fin Heat Sink

Introduction

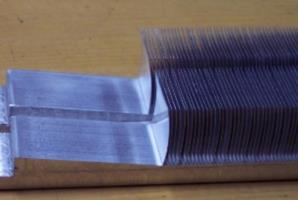

Skived Fin Heat Sinks are crafted from high-purity aluminum or copper, ensuring excellent thermal conductivity and durability. The skiving process creates ultra-thin, high-density fins from a single metal block, eliminating joints for enhanced strength. Surface finishes like anodizing and chemical conversion coating for aluminum and nickel plating and anti-oxidation for copper provide corrosion resistance and improved wear durability.

|

|

| Skiving machine producing aluminum heat sink | Aluminum block and skived heat sink |

Product Details

The Skiving Fin Heat Sink is manufactured using a precise skiving process, where fins are carved directly from a solid metal block-typically aluminum or copper-using specialized cutting tools. This method forms continuous, integral fins that remain firmly attached to the base, enhancing heat transfer between the base and the fins. One of the key advantages of this process is the high aspect ratio of the fins, which allows for a greater surface area within a compact footprint.

These heat sinks are designed to optimize airflow, making them ideal for both passive and forced convection systems. With their fine, closely spaced fins, Skiving Fin Heat Sinks achieve exceptional performance even in limited-space environments. The absence of thermal interface material between the fins and base also contributes to their excellent heat dissipation capability.

Skiving allows customization of fin height, thickness, and pitch, enabling tailored solutions to meet the specific needs of different applications. These heat sinks are widely used in sectors such as telecommunications, automotive electronics, industrial control systems, and computing devices, where effective heat management is essential.

Business Advantage

High Thermal Conductivity Materials

Utilizes premium aluminum and copper alloys, ensuring optimal heat dissipation and efficient thermal management.

Advanced Skiving Process

Employs cutting-edge skiving technology for creating ultra-thin, precise fins that maximize surface area and improve cooling performance.

Durable Surface Finishing

Offers anodizing, copper plating, and other surface treatments that enhance corrosion resistance and improve overall durability.

Customization Options

Provides custom designs, including fin height, spacing, and base size, tailored to meet specific thermal management requirements.

Compact and Lightweight Design

Skiving fin heat sinks are designed to be space-efficient while maintaining superior performance, ideal for applications with limited space.

Cost-Effective Production

In-house manufacturing processes reduce costs and shorten lead times while maintaining high-quality standards.

Consistent Quality Control

Rigorous testing and inspection processes ensure each heat sink meets precise thermal and dimensional specifications.

Fast Turnaround Time

Streamlined production processes enable quick prototyping and rapid production for both small and large orders.

Broad Industry Applications

Skiving fin heat sinks are suitable for a wide range of industries, including electronics, telecommunications, automotive, and industrial systems.

Global Reach with Local Support

Expertise in managing international orders with strong customer support and efficient global logistics.

PowerWinx continues to innovate in the field of thermal solutions, developing enhanced Skiving Fin Heat Sink designs that meet the growing demands of next-generation electronics. Our commitment to R&D ensures that we stay ahead of technological trends, offering products that are not only efficient but also forward-compatible with future electronic systems.

In conclusion, the Skiving Fin Heat Sink represents a powerful and efficient thermal management solution for various electronic applications. Its high thermal performance, customization flexibility, and structural integrity make it a go-to choice for engineers and designers. With a focus on quality, innovation, and customer satisfaction, PowerWinx is your trusted partner for advanced heat sink solutions.

Specification

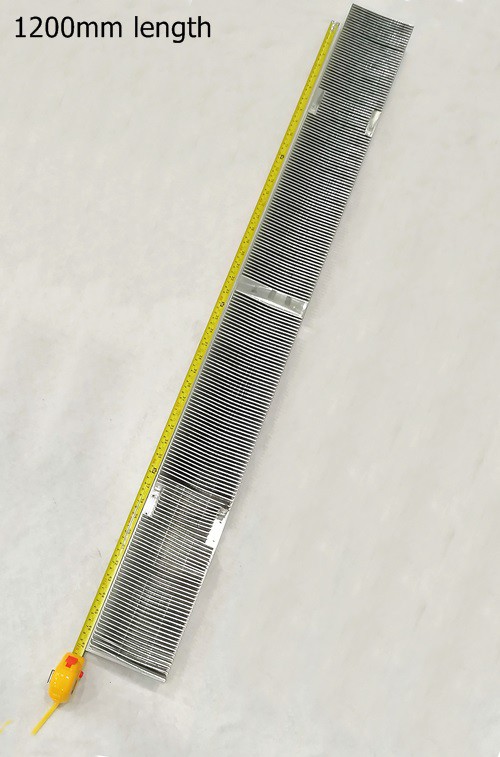

| Item name | Skiving fin heat sink |

| Material | Aluminum |

| Surface finish | Alodine |

| MOQ | 1 PCS |

| Sample L/T | 7-15 days for sample |

| Size | 1200*120*75 mm |

| Packing | Safety packing |

| Application | LED heat sink |

FAQ:

What materials are used for PowerWinx skiving fin heat sinks?

We use high-performance materials like aluminum and copper, selected for their excellent thermal conductivity and durability to ensure efficient heat dissipation.

How does the skiving process improve the performance of the heat sink?

The skiving process creates ultra-thin, precise fins with a large surface area, allowing for enhanced heat dissipation and better cooling performance, even in compact designs.

What surface finishes are available for PowerWinx skiving fin heat sinks?

Surface finishes like anodizing and chemical conversion coating for aluminum and nickel plating and anti-oxidation for copper

Can PowerWinx provide customized skiving fin heat sinks?

Yes, We offer tailored designs, including customized fin height, spacing, and base size, to meet specific thermal management needs for a variety of applications.

Hot Tags: skiving fin heat sink, China skiving fin heat sink manufacturers, suppliers, factory, experienced die casting, gravure printing cnc machining, fabrication cnc machining, polishing die casting, new die casting techniques, die casting capabilities