High quality heat pipe

1.Product Introduction

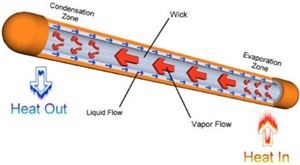

A heat pipe is constructed using a metal tube that is sealed under a partial vacuum. Inside the copper heat pipe is an inner wick lining that acts as a capillary material for a small amount of fluid. When heat is applied to the heat pipe surface in the evaporator region, the fluid is heated. Due to the vacuum, the fluid vaporizes more easily. This phase change from liquid to vapor increases pressure. As pressure rises, the vapor naturally flows to the cooler section of the heat pipe. Heat is released as the vapor condenses back into a liquid. The liquid then returns to the warm region, where the cycle repeats as heat is applied to that section.

There are three common methods used in heat pipe construction:

Grooved: Low cost but less effective against gravity.

Wire Mesh: The most commonly used method.

Sintered: Offers the highest performance but also the highest cost.

Schematic of heat pipe function Most common heat pipe methods

2.Product Details

PowerWinx offers heat pipe manufacturing in various shapes, sizes, and performance characteristics to complement its custom heat sink designs. Their high thermal conductivity, flexibility in bending and shaping, and long lifespan make heat pipes an ideal upgrade from solid metal heat sinks and, in some cases, an alternative to pumped liquid cooling systems.

High quality heat pipe

3. Specification

|

Item name |

High quality heat pipe |

|

Material |

C1100 |

|

Surface finish |

Anti-Oxidation |

|

MOQ |

500 PCS |

|

L/T |

7 days for tooling and 7-10 days for sample |

|

Size |

250*7* 2mm |

|

Packing |

Safety packing |

|

Application |

Heat pipe heat sink |

4.Part Features

- Excellent heat transfer

- Smooth finish

- Variety of shapes

- Customized designs

5.Business Advantage

- Extensive manufacturing capabilities

- Understanding of customers' unique requirements

- High-quality products

- Outstanding customer support

6.Delivery,Shipping

7.FAQ

1. What type of design files do you accept for quoting?

Please provide 2D & 3D drawings (STEP format) along with material, surface finish, and quantity information.

2. How long does a quotation take?

In most cases, we respond within a couple of days of receiving an RFQ. If there is a delay, we will notify you as soon as possible.

3. How long is the delivery for your industrial parts?

Delivery times vary depending on order quantity. Normally, 7 days for tooling and 7-10 days for samples.

4. Do you offer inspection reports?

Yes, all parts undergo quality control inspection before shipping, conducted according to the provided files.

Hot Tags: heat pipe, China heat pipe manufacturers, suppliers, factory, cnc machining for digital printing, cnc machining for value, cnc machining for offset printing, experienced die casting, die casting process, screen printing cnc machining