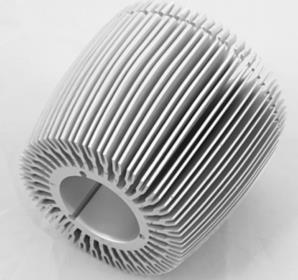

Round Heat Sink Extrusion

1.Product Introduction

Heat sink extrusions are the most common type of heat sinks used for thermal management today. They are manufactured by pushing hot aluminum billets through a steel die to achieve the final shape. The primary aluminum alloy used is 6063-T5, although other 6XXX alloys can be considered as needed.

During the extrusion process, the initial billets are typically 30-40 feet long and very soft. The material is stretched by gripping both ends to straighten it. Depending on the required final hardness, the material can undergo either air or over aging. After aging, the material is cut to its final length, and any additional machining (such as drilling holes or creating pockets) can be performed.

Extruded heat sinks usually come with a surface finish, such as anodizing, which enhances their thermal performance. Alternatively, they can be supplied with a chromate finish for corrosion protection, or as a primer before final painting or powder coating. Each extruded shape is uniquely designed to optimize both thermal efficiency and structural integrity.

|

|

| Aluminum extrusion line | Aluminum profile anodize process |

2.Product Details

Aluminum alloys are chosen for their lightweight nature, aesthetic appeal, high thermal conductivity, and ease of forming into complex shapes, making them ideal for cooling equipment. Aluminum heat sinks generally fall into three main types:

Flat wide shapes, resembling a fishbone or comb pattern

Round or oval shapes

Branching shapes

Compared to other materials, aluminum heat sinks have distinct characteristics such as closely spaced fins, forming troughs between adjacent fins, and a high aspect ratio. The design, manufacturing, and production of complex radiator extrusions pose significant challenges. Round heat sink extrusions are particularly popular in industries like LED and automotive manufacturing.

OEM round heat sink extrusion

3.Specification

|

Item name |

OEM round heat sink extrusion |

|

Material |

Aluminum 6063 |

|

Surface finish |

Customized |

|

MOQ |

500 PCS |

|

L/T |

15-20 days for tooling and 7-10 days for sample |

|

Size |

ø65 *60 mm |

|

Packing |

Safety packing |

|

Application |

LED heat sink |

4.Part Features

- Excellent heat transfer

- Round shape designed for LED heat sinks

- High fin density for improved performance

- Cosmetic finish

5.Business Advantage

- ISO 9001:2015 certified

- Expertise in machining and precision cutting

- Extensive experience in the aluminum industry

- Utilization of advanced equipment

6.Delivery,Shipping

7.FAQ

What is your delivery time?

15-20 days for tooling, typically 7-15 days for samples, and 20-30 days for mass production orders.

What thickness of anodizing can you provide? Can you do 15μm?

We can provide anodizing thickness ranging from 10 μm to 25 μm, or as per specific requirements.

What colors can you provide for powder coating? What is the thickness of your powder coating?

We offer a wide range of colors for powder coating; simply send us your color sample, and we will match it accordingly. Our standard powder coating thickness ranges from 60-80μm.

What industries do you serve?

As an OEM manufacturer, we can serve various industries, provided we receive drawings for quoting.

Hot Tags: round heat sink extrusion, China round heat sink extrusion manufacturers, suppliers, factory, die casting factory, decorative material cnc machining, wall material cnc machining, cnc machining for production, cost effective die casting, cnc machining for lead time