1.Product Introduction

Plastic injection molding is a manufacturing process used to produce parts in large volumes, typically for mass-production where the same part is replicated thousands or millions of times consecutively. The primary advantage of injection molding is its scalability for mass production. Once initial costs are covered, the per-unit cost in injection molding is significantly low and tends to decrease further with higher production volumes. This method is widely employed by custom molders at injection molding companies.

|

|

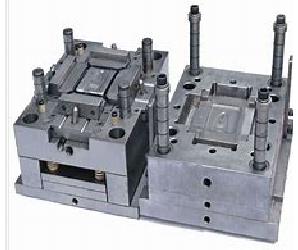

| Plastic injection machine | Plastic injection mold |

2.Product Details

We specialize in OEM plastic injection molded parts serving various industries worldwide. Our focus is on providing high-quality injection molded plastics at competitive prices with rapid turnaround times. Injection molding results in low scrap rates compared to traditional manufacturing processes like CNC machining. It also offers high repeatability, ensuring consistent quality across large production runs.

OEM plastic injection molded parts

3.Specification

|

Item name |

OEM plastic injection molded parts |

|

Material |

PP |

|

Surface finish |

Clean |

|

MOQ |

1000 PCS |

|

L/T |

30-40 days for mould and 2-4 days for samples |

|

Size |

55*50 mm |

|

Packing |

Safety packing |

|

Application |

Machinery |

4.Part Features

- High efficiency

- Lightweight

- Strength

- Cost-effectiveness

5.Business Advantage

- ISO 9001:2015 certified

- Innovative manufacturing solutions

- Lifetime mold guarantee

- Inventory management

- Turnkey Manufacturing - Design, Mold Making, and Injection Molding

6.Delivery,Shipping

7.FAQ

How much do your services cost?

Costs vary based on the project's specifics. Each project is unique and requires different timelines and resources.

How is my confidential information protected?

With over 10 years of experience, we prioritize integrity and confidentiality. We are willing to sign an NDA (Non-Disclosure Agreement) to safeguard your information.

What information is needed for quoting a molding project?

Please provide details such as quantity needed, preferred materials, 3D and 2D drawings, and part samples if available.

Do I need to visit your facility to start the project?

While you are welcome to visit for an initial meeting, we accommodate clients worldwide through communication channels like email and telephone.

Hot Tags: plastic injection molded parts, China plastic injection molded parts manufacturers, suppliers, factory, quality die casting, die casting suppliers, value cnc machining, varnish cnc machining, cnc machining for production, small batch die casting