1.Product Introduction

Sheet metal fabrication is a classification of manufacturing processes that shape a piece of sheet metal into the desired part through material removal and/or material deformation. Sheet metal, which acts as the workpiece in these processes, is one of the most common forms of raw material stock. The material thickness that classifies a workpiece as sheet metal is not clearly defined. However, sheet metal is generally considered to be a piece of stock between 0.006 and 0.25 inches thick. A piece of metal much thinner is considered to be "foil" and any thicker is referred to as a "plate". The thickness of a piece of sheet metal is often referred to as its gauge, a number typically ranging from 3 to 38. A higher gauge indicates a thinner piece of sheet metal, with exact dimensions that depend on the material. We are a full service sheet metal fabrication factory that has tremendous In house capabilities to produce quality sheet metal fabrication out of aluminum, stainless or carbon steel.

|

|

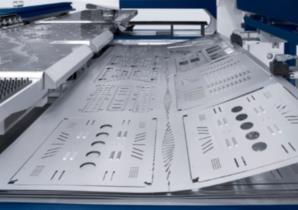

| Sheet metal punching NCT process | Sheet metal welding process |

2.Product Details

We specialize in custom sheet metal fabrication to create different objects that are critical to your operations. Steel and stainless steel fabrication is the process of creating a product by cutting, bending, and shaping steel alloy. Steel alloy is a combination of elements added together consisting of mainly iron, but also other metals including nickel, silicon, boron, and others. Steel costs less than aluminum. Aluminum is much more malleable than steel, meaning it is more easily bent and shaped. Steel, although more difficult to shape, is extremely stronger and harder than aluminum. Steel must be painted or coated to prevent rust and corrosion. We have more than 10 years experience in steel sheet metal fabrication to produce variety products.

Steel sheet metal fabrication factory

3.Specification

|

Item name |

Steel sheet metal fabrication factory |

|

Material |

Steel |

|

Surface finish |

Clean |

|

MOQ |

500 PCS |

|

Sample L/T |

7-10 days for sample |

|

Size |

250* 180 mm |

|

Packing |

Safety packing |

|

Application |

Machinery |

4.Part Features

4-1. Strong enough

4-2. Magnetic grades available

4-3. Durable

4-4. Heat treatable

5.Business Advantage

1. Reliable Packaging

2. Friendly, Knowledgeable Staff

3. Prompt, Reliable Service

4. In Business for Over 10 Years

6.Delivery,Shipping, and Serving

7.FAQ

1. What Is the Difference Between Stainless and Ordinary Steel?

All steel is iron based, but stainless steel contains chromium at 10% or more by weight.

2. What is your standard lead time?

We will work with you to meet the lead times that your company and/or customers require.

3. Is Steel Magnetic?

Because the predominant element in steel-iron-is magnetic, most steels do have magnetic properties.

4. What industries do you support?

Currently, we support a wide range of end users including: construction, signage, electrical enclosures, food service, medical, polyethylene, air movement, railroad/transportation, agribusiness, utility vehicle, and point-of-sale displays. We are always looking for new opportunities in new market places, so please do not hesitate to inquire about your specific demands.

Hot Tags: steel sheet metal fabrication, China steel sheet metal fabrication manufacturers, suppliers, factory, linoleum floor cnc machining, cnc machining for on time delivery, consistent die casting quality, tight tolerance die casting, cnc machining for value, innovation cnc machining