High quality large heat sink

Introduction

Our large heat sinks are built from high-quality aluminum or copper, offering exceptional thermal conductivity and long-term durability. Designed for high-power applications, they feature optimized fin structures and extended surface areas to maximize heat dissipation. Manufactured using extrusion, bonded fin, folded fin or brazing techniques, these heat sinks maintain structural integrity under extreme thermal loads. Ideal for industrial equipment, power electronics, and energy systems, their robust design ensures reliable performance even in harsh environments requiring superior thermal management.

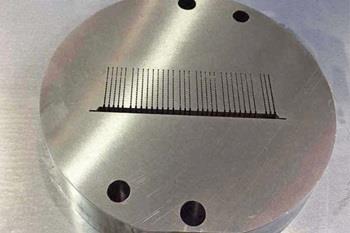

Extrusion process Extrusion die

Product Details

A large heat sink is a mechanical device constructed to absorb and dissipate heat from electronic components into the surrounding air or liquid environment. These heat sinks are commonly used with high-wattage devices such as power inverters, data servers, LED lighting systems, and industrial power supplies. Their expanded surface area, typically made from materials with high thermal conductivity like aluminum or copper, allows for efficient heat transfer and dissipation.

PowerWinx manufactures large heat sinks using several advanced processes, including CNC machining, skiving, extrusion, and friction stir welding. These techniques allow us to offer flexible design options to meet the complex requirements of different industries. Our heat sinks can be customized in size, fin density, and mounting configurations to ensure optimal performance and seamless integration into your application.

A distinguishing feature of our large heat sink products is their high fin-to-base strength and excellent thermal conductivity. Whether your application requires passive cooling or is part of a hybrid liquid-cooling system, our solutions deliver high heat dissipation with minimal airflow resistance. In addition, all our heat sinks undergo rigorous quality control to ensure structural integrity and thermal reliability over time.

High quality large heat sink

Specification

|

Item name |

High quality large heat sink |

|

Material |

Aluminum 6061 |

|

Surface finish |

Clean |

|

MOQ |

500 PCS |

|

L/T |

15-20 days for tooling and 7-10 days for sample |

|

Size |

600*300*50 mm |

|

Packing |

Safety packing |

|

Application |

Chillers |

Business Advantage

Expertise in Large-Scale Thermal Solutions

Specialized in designing and manufacturing large heat sinks for high-power industrial and electronic applications.

Advanced Manufacturing Capabilities

Utilizes extrusion, bonded fin, friction welding, and vacuum brazing processes to produce large heat sinks with excellent structural strength and thermal performance.

High-Quality Materials

Uses premium-grade aluminum and copper to ensure optimal heat conductivity and long-term reliability.

Custom Design Support

Offers tailored solutions including fin structure, base thickness, and mounting features to meet specific thermal and mechanical requirements.

Precise CNC Machining

In-house CNC capabilities provide tight tolerance control and integration of complex geometries or assembly features.

Durable Surface Treatments

Provides anodizing, powder coating, or nickel plating for enhanced corrosion resistance and extended product life in harsh environments.

Efficient Prototyping and Production

Fast turnaround on both prototypes and volume production, ensuring timely delivery for development and production timelines.

Thermal Simulation & Engineering Support

Offers thermal analysis and design optimization services to maximize cooling efficiency in demanding applications.

ISO-Certified Quality Assurance

Rigid quality control processes ensure consistent performance and adherence to international manufacturing standards.

Global Logistics & Support

Reliable international shipping and responsive technical support ensure smooth project execution from design to delivery.

Delivery,Shipping

FAQ:

What materials are used for PowerWinx large heat sinks?

We use high-quality aluminum and copper, selected for their excellent thermal conductivity and durability in high-power cooling applications.

Which manufacturing processes are used for producing large heat sinks?

Depending on the design and application, PowerWinx employs extrusion, bonded fin assembly, ,folded fin,skiving fin,etc....to ensure optimal performance and structural integrity.

Can PowerWinx provide customized large heat sinks for specific applications?

Yes, We offer fully customized designs, including fin layout, base size, mounting features, and surface finishes tailored to specific thermal and mechanical requirements.

What surface finishes are available for large heat sinks?

Available finishes include anodizing, powder coating, and nickel plating,etc...., all of which enhance corrosion resistance and extend service life in harsh environments

Are you trading company or manufacturer?

We are manufacturer, Located in Dongguan, Guangdong, China .

Hot Tags: large heat sink, China large heat sink manufacturers, suppliers, factory, machinery die casting, competitive die casting prices, standard die casting, environmentally friendly die casting, screen printing cnc machining, specialized die casting