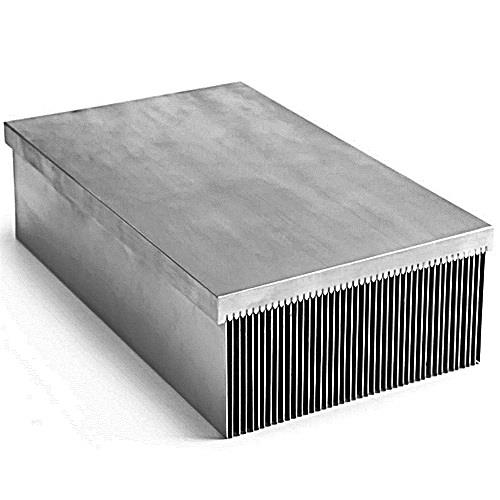

High quality bonded fin heat sink

1.Product Introduction

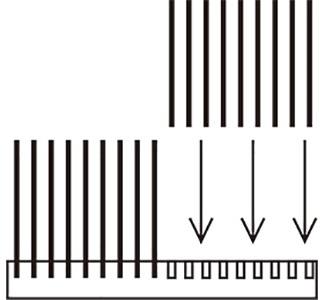

Bonded fin heat sinks are an assembly of a grooved base with individual fins bonded into the grooves. This type of heat sink fabrication allows for higher fin densities and fin aspect ratios than what is manufacturable with extrusion methodologies, greatly improving thermal performance as compared to extruded heat sinks due to increased surface area. Bonded fin types can be constructed in a few ways. Grooved bases can be extruded, die cast, or machined. Machining can allow for additional features like embedded heat pipes, vapor chambers, or encapsulated graphite heat spreaders. Fins are either punched from coil stock or cut from thin plate stock. The fins are inserted into the base grooves and are joined by epoxy, brazing, or soldering.

Schematic assembly view Bonded fin heat sink assembly

2.Product Details

In very demanding power applications where significant heat is generated in a small volume, Methode's bonded-fin designs can meet your packaging needs by increasing the heat sink surface area without increasing volume, reducing thermal resistance by fifty to sixty-six percent. Bonding fins to a heat sink removes the design-limiting fin extrusion ratio found in extruded heat sinks.

· Aluminum, copper or mixed metal bonded-fin assemblies

· Copper base and aluminum fin

· Fins fabricated from sheet metal or extrusion

· Increased surface area

· Lower thermal resistance

3. Specification

|

Item name |

High quality bonded fin heat sink |

|

Material |

Aluminum 6061/1100 can be copper |

|

Surface finish |

Clean can be plating, etc... |

|

MOQ |

100 PCS |

|

L/T |

15-20 days for tooling and 7-10 days for sample |

|

Size |

300*200*70 mm |

|

Packing |

Safety packing |

|

Application |

Power rectification equipment |

4.Part Features

4-1. Aluminum 6061 for base and Aluminum 1100 for fins.

4-2. Excellent heat conductivity

4-3. Nice finish

5.Business Advantage

1. One-stop solution

2. SGS & ISO audited

3. Experienced manufacture

4. High supply capacity

6.Delivery,Shipping

7.FAQ

1. Are you trade company or manufactuer?

We are China professional manufacturer of customizing various thermal solution products.

2. What characteristics make a heatsink a good one?

High quality surface; Good aerodynamics; Good thermal transfer within the heats ink; Perfect flatness of the contact area; Good mounting method.

3.What mode of transport do you use?

Air transportation, UPS,DHL,FedEx, sea shipping etc...

4.Can you provide OEM Service?

Sure, we can, the service process mainly includes 5 steps:

Step 1: Please send us a detail drawing or physical sample.

Step 2: Our engineer will make the mold/die design based on your drawing or sample.

Step 3: Share your detailed quotation both mold/die and product.

Step 4: Test our product for final confirmation.

Step 5: Mass production after final confirmation.

Hot Tags: bonded fin heat sink, China bonded fin heat sink manufacturers, suppliers, factory, die casting expertise, cnc machining for on time delivery, value cnc machining, aerospace die casting, simple die casting, lacquer cnc machining