Introduction

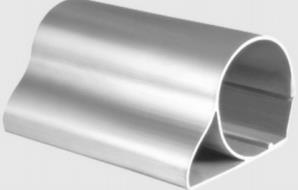

PowerWinx's Magnesium Profile Extrusion offers exceptional strength-to-weight ratio and corrosion resistance, ideal for lightweight and durable applications. We utilize advanced extrusion technology and high-quality magnesium alloys such as AZ31,AZ61 and AZ80, ensuring superior mechanical properties. The profiles are designed with precision to meet specific client requirements, offering complex shapes and tight tolerances. This process allows for custom, high-performance components used in industries like aerospace, automotive, and electronics, where lightweight, durable, and corrosion-resistant materials are critical.

|

|

|

Magnesium extrusion machine |

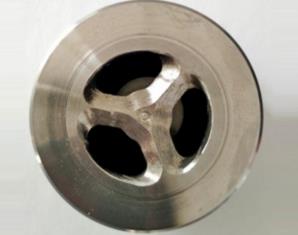

Profile extrusion die |

Product Details

It's basically the go-to move if you're after something super light but still tough. They use these fancy magnesium alloys like AZ31 and AZ91 (which are way cooler names than they sound, trust me), and the stuff is kind of a dream to work with. Cuts like butter, doesn't rust up at the first sign of moisture, and it's got that strength-to-weight thing going on that makes engineers drool.

Honestly, you'll see this stuff popping up everywhere: planes, cars, laptops, you name it. The best part? You can get all these weird shapes and dimensions out of the extrusion process-crazy detail, tight tolerances, the whole nine yards. Perfect for tricky projects like structural frames, housings, or those fancy heatsinks that keep your gadgets from melting. And yeah, since it weighs next to nothing, everything runs smoother and uses less energy. Who doesn't want that?

So, bottom line: magnesium extrusions are tough, reliable, and won't burn a hole in your wallet. If your gig is building lighter, smarter, or more badass stuff, this is the place to look.

Key product characteristics include:

Lightweight Construction: Magnesium is 33% lighter than aluminum and 75% lighter than steel, making it ideal for applications where weight reduction is critical.

High Strength-to-Weight Ratio: Despite its low density, magnesium provides impressive structural integrity, essential for load-bearing applications.

Excellent Thermal and Electrical Conductivity: This makes extruded profiles suitable for use in heat dissipation and electronic enclosures.

Good Machinability: Post-processing operations such as CNC machining, drilling, and tapping are easier compared to many other metals.

Applications of magnesium extruded profiles are diverse. In the automotive sector, they are used for seat frames, dashboard supports, and battery housings. In consumer electronics, magnesium extrusions are valued for their heat dissipation and shielding properties. Aerospace engineers leverage magnesium profiles for interior components to reduce aircraft weight and improve fuel efficiency.

Magnesium profile extrusion

Specification

|

Item name |

High quality magnesium profile extrusion |

|

Material |

Magnesium alloy |

|

Surface finish |

Passivation |

|

MOQ |

500 PCS |

|

L/T |

10-15 days for tooling and 7-10 days for sample |

|

Size |

370*150 mm |

|

Packing |

Safety packing |

|

Application |

Projector frame |

Business Advantage

Look, magnesium profile extrusion? Kinda a game-changer- seriously. You get the best of both worlds: super light (honestly, you'll wonder if you're even holding anything) and still tough as nails. Think about those fancy alloys, like AZ31 or AZ91- these bad boys are the MVPs behind stuff that needs to be both strong and featherweight.

And get this- you're not just dropping pounds off your products for fun. Less weight means better energy efficiency, whether it's electric cars, planes, or even the electronics cluttering up your backpack right now. Companies? They're loving the savings on shipping and fuel. Extra durability's just icing on the cake.

Plus, you can crank out wild designs. Complex shapes? Bring 'em on. Tight tolerances? No sweat. The production speed makes it a total win for any business trying to keep up with demand. And yeah, magnesium's not just a pretty face either- easy to machine, shrugs off corrosion, sticks around for the long haul.

Bottom line: if you're in a cutthroat industry and you're not looking at magnesium extrusion, honestly, what are you even doing? It's your ticket to innovation, staying ahead of the pack, and not wrecking the planet in the process. Don't sleep on it.

Delivery,Shipping

FAQ:

1: Are your products customized ?

Yes, the products in the website are only the common type or the previous types, we can supply the new products according to your requirements or drawings.

2: Are you a factory or trading company?

We are direct manufacturer located in Guangdong province, and have our equipment.

3: What's the delivery time for samples and mass production?

After finish tooling, 7-10 days for samples and for mass production , it depends on quantity.

4: What industries use PowerWinx's magnesium extrusions?

Our magnesium profiles are widely used in aerospace, automotive, consumer electronics, and industrial applications where lightweight and durable materials are essential.

Hot Tags: magnesium profile extrusion, China magnesium profile extrusion manufacturers, suppliers, factory, die casting production, debossing cnc machining, production cnc machining, cnc machining for wallpaper, stain cnc machining, low pressure die casting